Lavina Eco

quick maintenance,

grinding and polishing

Technology

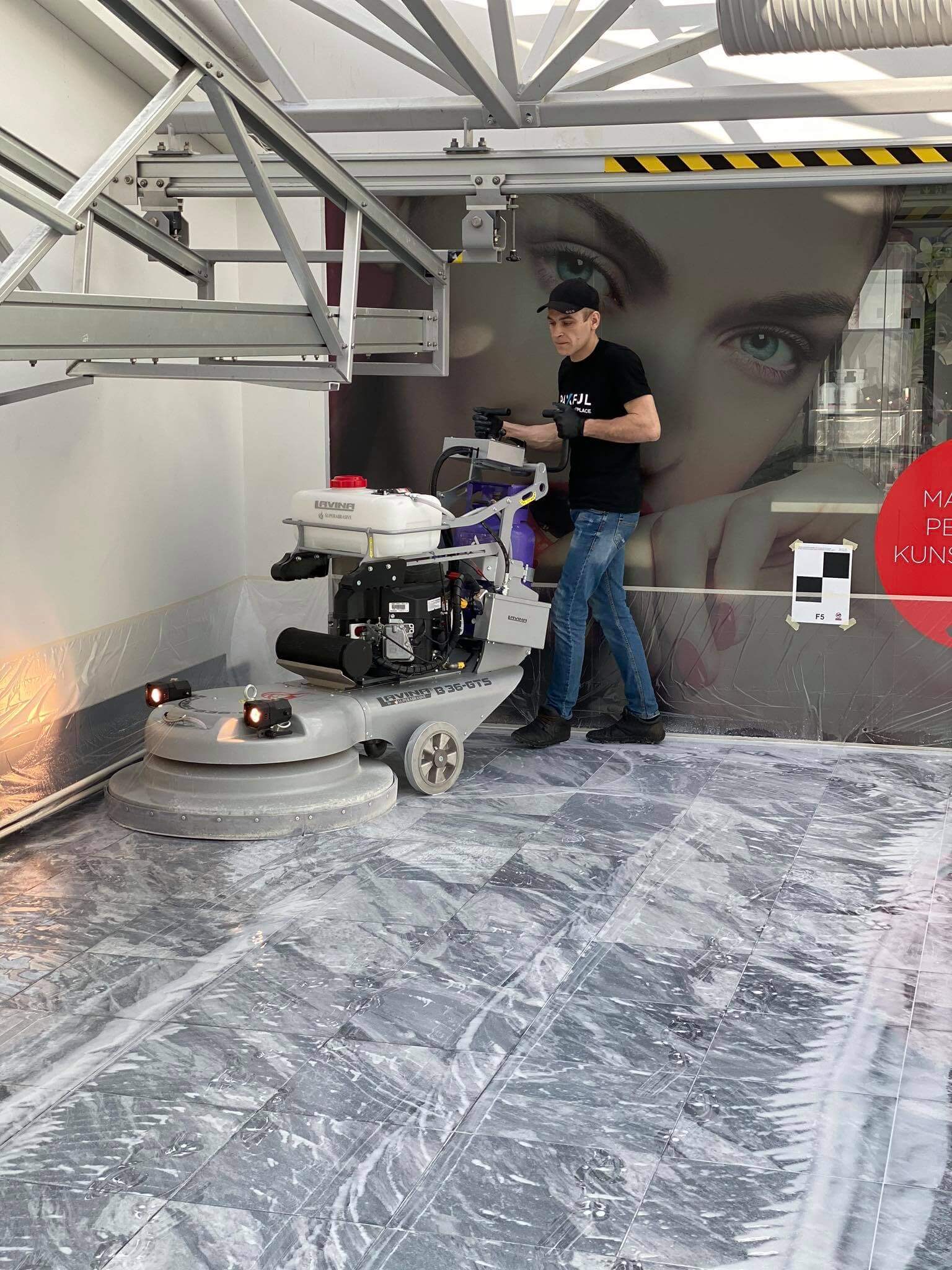

All main works in Lavina Eco technology are performed with the LB36GT-S machine. It is a propane floor polisher with 3 high-speed planetary 14-inch heads. The machine is powered by a 13.3 kW Kawasaki engine with a catalytic converter that allows it to work in closed rooms. The machine also has many other advantages, such as lighting of the working space or a floor misting system.

Light grinding is obtained by mounting the DS diamond screens (DS-14W) on the machine. These are lightweight metal screens covered with a layer of microdiamonds of a specific grit sequence – 220, 400, 600. After grinding with these grits, the floor should be ready for polishing after prior hardening.

Polishing is achieved using SupraShine High Performance diamond pads. The pad consists of a carrier made of a flexible but durable material and a layer with microdiamonds. In this technology we use 1800 and 3500 grits.

In addition, to obtain the correct effect, we need to use a concrete hardener and sealer. Here we recommend Ultralit products. Ultralit Hard Eco is a concrete hardener with a concentration of 8% lithium silicate. Penetrates the floor and hardens its structure and increases durability. Moreover, we recommend Ultralit Gloss as a sealer. It contains lithium which closes the concrete surface and protects it against the ingress of liquids.

Lavina Eco step by step:

- 1) Grinding with DS screens 220 grit

- 2) Grinding with DS screens 400 grit

- 3) Grinding with DS screens 600 grit

- 4) Hardening the floor with Ultralit Hard Eco

- 5) Polishing with Suprashine HP diamond pad 1800 grit

- 6) Floor sealing with Ultralit Gloss

- 7) Buffing with Suprashine diamond pad 3500 grit